At Apex Aluminum we value your product, which is why we offer a variety of packaging options to cater to your specific needs. No matter the type or size of extrusion, our packaging team will focus on protecting your product, and packaging it to your specifications. Please contact us if you have any questions regarding our packaging solutions.

To protect your shipment, included as Standard, our bare bundles have top and bottom wood strapping, cardboard strips and corner boards.

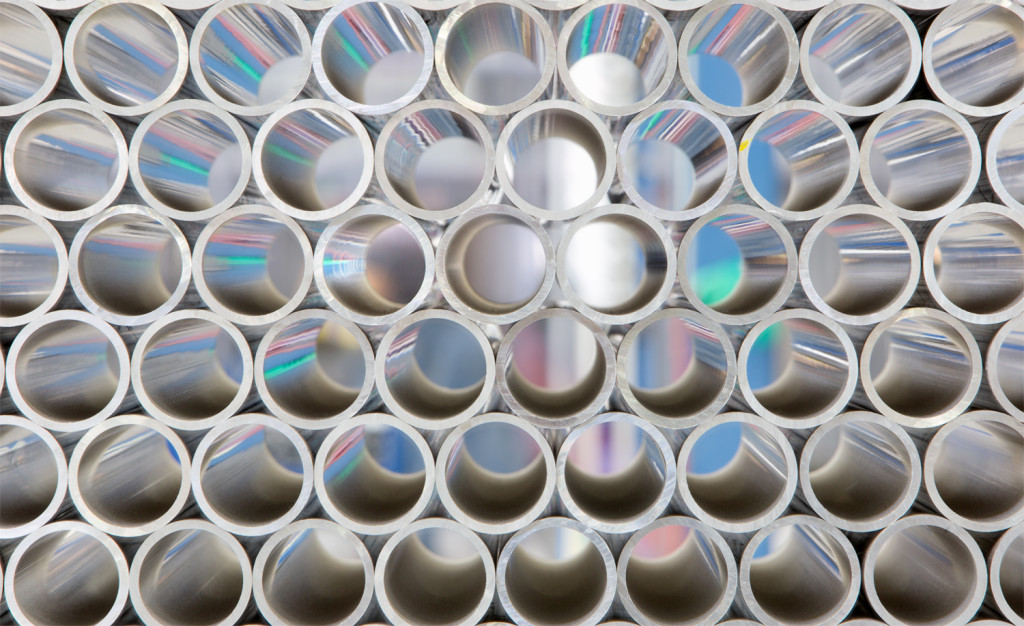

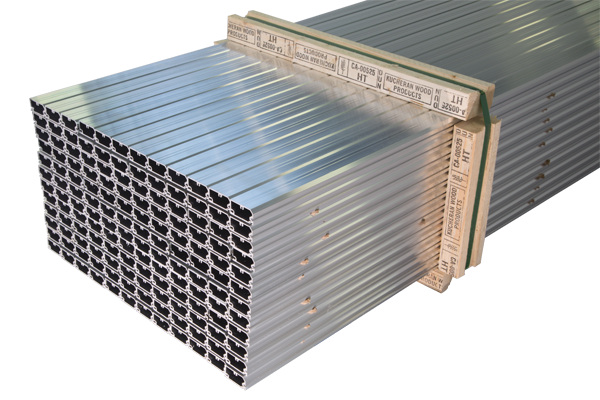

Standard Bundles

Mill-Finish Bundle Top & Bottom Wood Strapping

Two pieces of wood dunnage are placed on the top and bottom of the bundle, strapped together and repeated at regular intervals along the length of the bundle. This is one of our most common forms of packaging and works best for structured shapes.

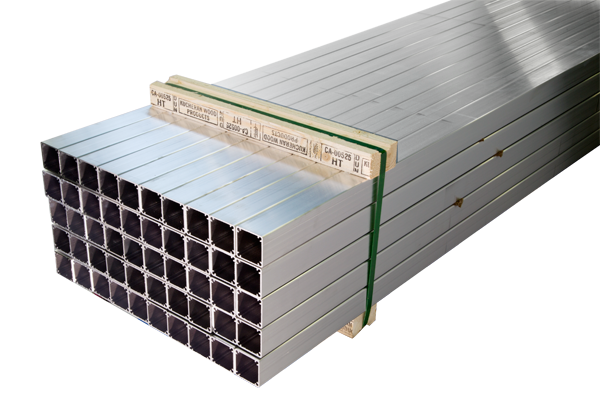

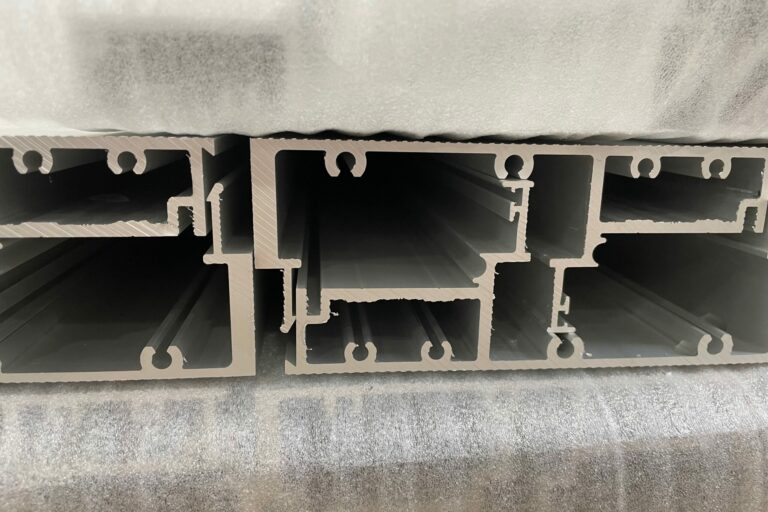

Stripping

Strips of chipboard are placed 3 feet apart along each layer of the bundle. The chipboard will ensure the bundle is balanced and offer support and separation between layers to prevent scratches on the finished product.

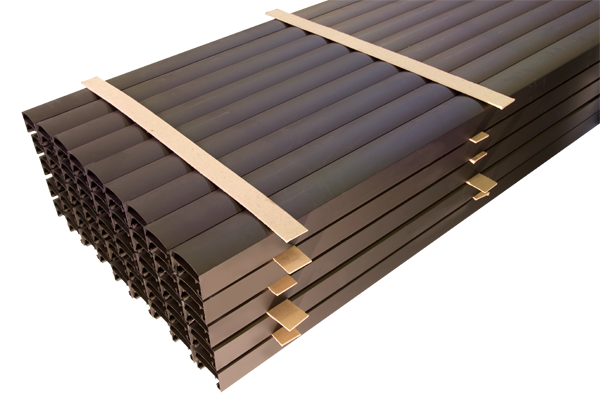

Corner Board

Cardboard corner protectors are placed between the centre band points and all four corners of the bundle, to provide protection from forklift handling, transport & stacking, as well as protecting the extrusions from any friction caused by the structured wood. This method of packing is only available for anodized bundles.

External Protection Options

Fully covered Cardboard & Shrink Wrap*

The bundle is fully covered with cardboard, then plastic wrapped to provide protection from debris, handling and inclement weather. This method of packing is only available for anodized bundles.

Mill-Finish Bundle Four Sided Wood Strapping*

Wood dunnage is placed on all sides of the bundle, strapped together and repeated at regular intervals along the length of the bundle. The additional support ensures the bundle is fully contained during transport and prevents the possibility of the bundle collapsing. This is one of our most common forms of packaging and works best for structured shapes.

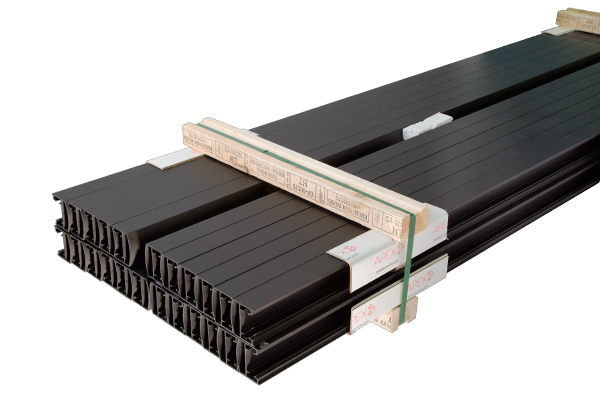

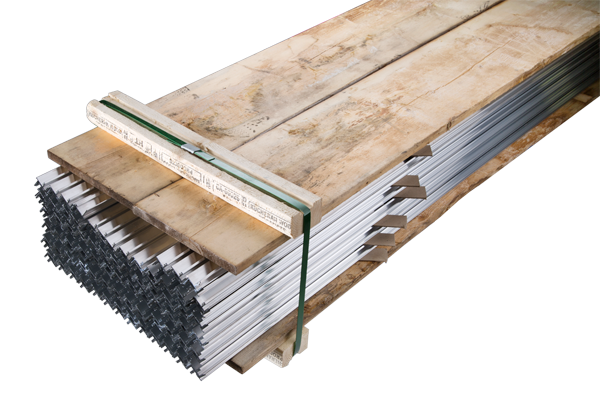

Lumber Support*

For extrusions of a more fragile nature, lumber planks are placed along the top and bottom of the bundle, adding extra support and structure, to ensure protection during transit.

Internal Separation Options

Foam Weaving*

Foam sheeting is inter-weaved between each individual extrusion, layer by layer, to provide superior protection from surface rubs & scratches during transit. Foam weaving can be added to any packaging method.

Foam or Cardboard Layer*

Foam or Cardboard is inserted between rows in the bundle to give improved protection during transportation.

*Subject to additional charges